- Provides stable, continuous heating and ventilation

- Long-lasting construction for longer use

- High efficiency and capacity

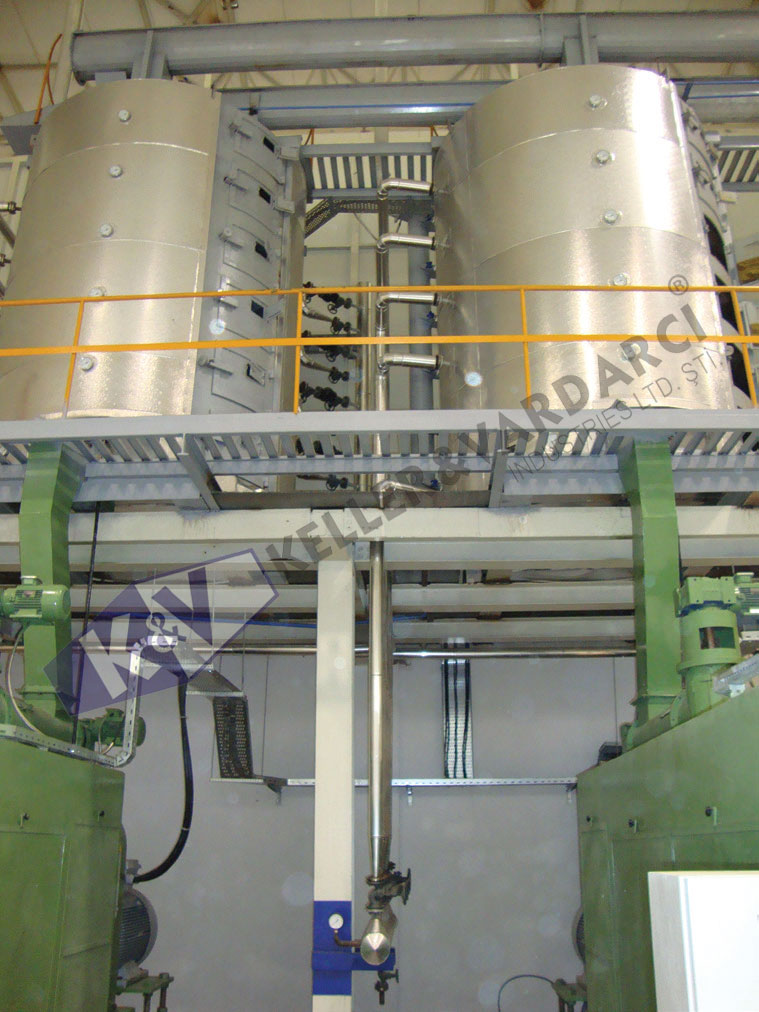

The cooker is designed as a rigid structure all steel frame for the conditioning of oilseeds during the preparation process before to the oil pressing or flaking. It is suitable for cooking different oilseeds, such as cottonseed, sunflower seed, rapeseed, peanut, soybean, etc.

The cooking process is generally carried out in a multi-stage oven with its own specially design scrappers mounted on the main vertical shaft in each floor, in a structure in which the oilseeds can progress vertically between steam-heated plates. The number and the diameter of the plates are dependent on the type of the seed and the capacity desired.

The machine is specially isolated and chrome coated. It is equipped with a special coupling system in order to prevent the damaging which could be caused by squeezing.

We produce the steam aspiration system from stainless steel.

We manufacture multiple stage flats Cooker according to our customer needs.

Technical Description

Model |

Dimensions (mm) |

Capacity |

Motor Power (H.P.) |

||

A |

B |

C |

|||

KV-T-05 |

2550 |

2300 |

4050 |

150 (± 10%) |

30 |

KV-T-06 |

3060 |

2750 |

4630 |

200 (± 10%) |

40 |

Keller & Vardarcı Industries Company has the right to make changes in the capacity and dimensions of its products.

COOKER: Precision Conditioning for Oilseeds

In the world of oilseed processing, where the quality of the final product hinges on precise conditioning, the COOKER stands as a pivotal solution. This advanced equipment offers a range of features that redefine the standards of seed conditioning, including stable and continuous heating, long-lasting construction, high efficiency, and capacity.

Key Features:

Stable, Continuous Heating and Ventilation: The COOKER provides a stable and continuous heating and ventilation system, ensuring that oilseeds are perfectly conditioned during the preparation process before oil pressing or flaking.

Long-Lasting Construction: Constructed with a rigid all-steel frame, the COOKER is engineered for longevity, guaranteeing extended use and reliable performance.

High Efficiency and Capacity: The equipment boasts high efficiency and capacity, making it suitable for cooking a variety of oilseeds, including cottonseed, sunflower seed, rapeseed, peanut, soybean, and more.

Precision Conditioning for Oilseeds:

The COOKER plays a critical role in conditioning oilseeds before they undergo further processing. It prepares the seeds by subjecting them to a carefully controlled cooking process.

Multi-Stage Oven with Scrappers:

- The cooking process typically occurs in a multi-stage oven equipped with specially designed scrappers mounted on the main vertical shaft on each floor.

- This structure allows the oilseeds to progress vertically between steam-heated plates.

- The number and diameter of the plates are customized based on the type of seed and the desired processing capacity.

Isolated and Chrome Coated:

The COOKER is specially isolated and chrome coated, ensuring both the efficiency of the cooking process and the longevity of the equipment.

Special Coupling System:

The machine is equipped with a special coupling system to prevent damage that may occur due to squeezing during operation.

Stainless Steel Steam Aspiration System:

The steam aspiration system is manufactured from stainless steel, further enhancing its durability and performance.

Customization for Varied Needs:

Multiple stage flats COOKER models are manufactured to meet the specific needs and capacity requirements of customers.

In conclusion, the COOKER is a testament to innovation and engineering excellence in the realm of oilseed processing machinery. Its stable and continuous heating, long-lasting construction, high efficiency, and capacity make it an indispensable asset for any oil processing facility. This machine not only ensures precise seed conditioning but also raises industry standards, where quality and efficiency are the keys to success. Invest in the COOKER and experience the future of oilseed conditioning, where precision and reliability are guaranteed.